Results of the July SimTech™ 2023 Injection Molding Challenge

First Place Goes to Tyler Barton of MVA Stratford, Inc. and this month’s Company Spotlight features Team Scientific Specialities Inc. Congratulations to Tyler and to Team Scientific Specialities, Inc. and all those who participated!

July 2023 SimTech™ Challenge Wrap Up

We’re pleased to announce that newcomer Tyler Barton of MVA Stratford, Inc. is this month’s Top Molder, followed by one other new comer, Christopher Musolf of MGS Mfg., and coming in for 3rd place is Earl Olson of Scientific Specialities, Inc. Congratulations Tyler, Christopher, and Earl, and congratulations to all who participated and earned scores.

Reclaiming the top spot on the Champions Leaderboard is our former TOP MOLDER Andrea Bricola from Draexlmaier Automotive of America, with Alexandru Crai of OMS Besser Group and Nick Vanspronsen from Toyota Boshoku following a hairs breath behind. Shining brightly in the company spotlight are three talented molding companies, Team Scientific Specialities, Inc., Team Preformed Line Products, and Team Falcon Plastics. These three company teams have demonstrated superior excellence in molding. Congratulations!! Job well done everyone! And, YES! You can put a team together. You only need 3 or more employees to make up a team and off you go? Join the fun and test your molding skill.

Special Insight on this Month’s Challenge

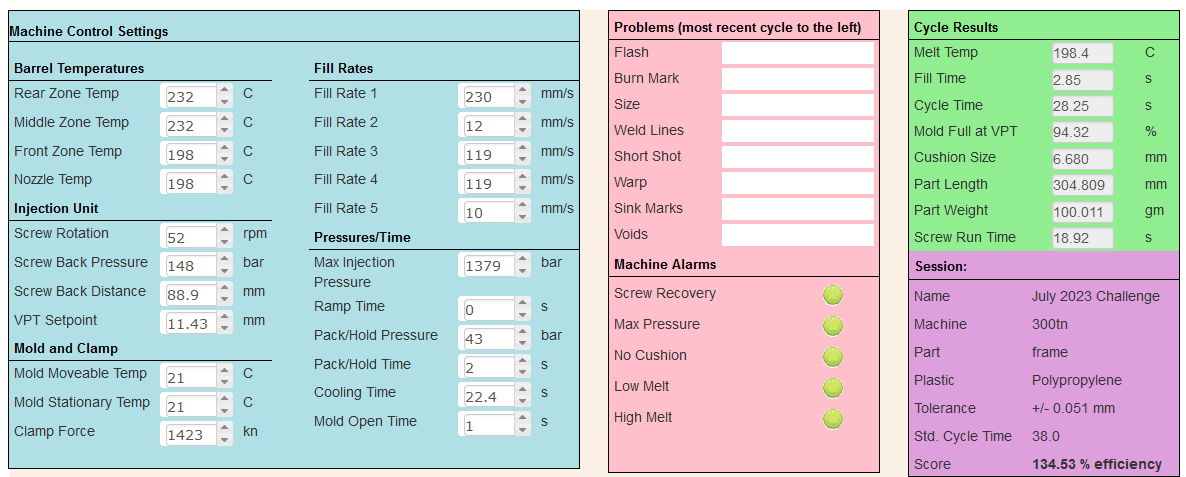

For the July Challenge, the top three finishers were separated by only 0.30 points so this month’s challenge was tightly contested. The final winning setup from Tyler Barton featured a process that minimized the material temperature entering the mold. A reverse tapered heating profile was used because this month’s challenge featured a semi-crystalline material with a machine that was configured with a “general purpose” screw. The top finishers utilized the fill rate control system on the SimTech molding machine, providing the fastest flow rate of the material into the mold without creating fill related defects. Finally, the cooling time was set at a minimum by utilizing the mold temperature control settings providing adequate cooling rate for the final plastic part. Well done molders!

Individual Winners

- 1st Place – Tyler Barton from MVA Stratford Inc. 134.53

- 2nd Place – Christopher Musolf from MGS Mfg. 134.37

- 3rd Place – Earl Olson from Scientific Specialties Inc. 134.23

Company Winners

The COMPANY category consists of companies who have three or more employees participating, and for this month’s challenge, the top three winning companies included:

Company Spotlight:

- 1st Place – Scientific Specialties Inc. 134.02

- 2nd Place – Preformed Line Products 133.96

- 3rd Place – Falcon Plastics 133.24

Champions Leaderboard:

- 1st Place: Andrea Bricola, Draexlmaier Automotive of America 134.82

- 2nd Alexandru Crai, Oms Besser Group 134.78

- 3rd Nick Vanspronsen, Toyota Boshoku 134.73

The Set-up for Tyler Barton, this month’s Top Molder.

To learn more about our monthly SimTech Molding Challenges visit details here. To see how you or your fellow molders ranked this month, check out the leader board by clicking here and select a month from the drop down menu.

As always, we’ll be announcing the over all 2023 ProMolder Champion after we tally all the scores from the entire year. Start earning scores!

In the meantime, get ready for the next month’s challenge! Take advantage and pre-signup. Don’t miss out. Get on the list to win! Until then, keep on learning!

Having Fun with our Competitions?

Imagine the team of skilled molders you could create if SimTech was in your plant 24-7? Your employees could be improving their molding expertise in a safe, low-cost environment, building critical thinking and troubleshooting skills. And you can stage your own friendly in-house competitions. It’s proven that molding simulation is the best and most cost-effective way to become a better molder. You don’t want your employees making their mistakes or trying new techniques on the production floor at an actual machine—now that’s a costly way to learn. The simulation of complex processes is quickly becoming the gold standard of skill development. SimTech is the answer for injection molding.

Here’s just a few of the applications you can employ with SimTech:

Hiring Qualified Employees – Before hiring a potential employee, test their knowledge and skills with problem solving exercises in Simtech.

Technician Promotion – Give your candidates for promotion a test before you make that decision.

In-plant Competitions to promote learning and discussion – Have your own competitions amongst your team. Have a discussion on what process settings work and why.

Just hearing about this? Want to join in on all the fun? Sign up and learn more here.

To learn more about SimTech and all the other skill development courses Paulson offers, visit PaulsonTraining.com or call 1-800-826-1901; or contact us via email info@paulsontraining.com.